Cross contamination

The ideal industrial vacuum cleaners to minimise the risk of contamination in the pharmaceutical industry.

Chemical and pharmaceutical industries need to guarantee that products meet the highest quality standards. In this setting, cross-contamination is a big threat for product quality and can be avoided by following GMP (Good Manufacturing Practice) standards.

GMP requires the use of appropriate equipment and measures to prevent products from the risk of external contamination. Industrial vacuum cleaners with HEPA filtration are the tools best suited to reduce risks and ensure product quality. Pneumatic conveyors, instead, ensure that powders are transported safely, preventing the products from coming into contact with polluting agents and making sure the quality of the final products remains intact.

Industrial vacuum cleaners for general cleaning

Using industrial vacuum cleaners for scheduled workplace cleaning allows you to:

Achieve maximum hygiene in the workplace

Eliminate contaminating agents at the source

before they are released into the air

Ensure maximum production plant

hygiene and productivity

Recommended for this application

Vacuum cleaners to clean production lines

Pharmaceutical production machinery requires continuous maintenance to guarantee the efficiency and maximum quality of the final product. Solids, granules, and liquids constantly build up on these machines during work cycles and must be continuously removed to prevent unexpected malfunctions and production standstills. Using an industrial vacuum cleaner to directly remove excess materials from the processing machine guarantees efficiency, productivity and reduces the time needed to clean machinery like: Blister Machines, Tablet Making Machines, Capsule Filling Machines, and other processing machines.

Mastervac offers modular solutions, available in vertical or horizontal configurations, easy to install and integrate both on existing production lines and in locations with limited space available.

Vacuum cleaners for cleanrooms

Cleanrooms are areas that are controlled in terms of atmospheric pressure and particle pollution. The air inside must contain a very low amount of micro suspended dust particles and, therefore, must be very clean with very high hygiene levels. The vacuum cleaner range designed for these environments are certified for use up to ISO4, built in AISI316 stainless steel with mirror polishing, and the multiple filtration levels guarantee the outgoing air is completely clean. The entire range and accessories are autoclavable (except the vacuum cleaner head).

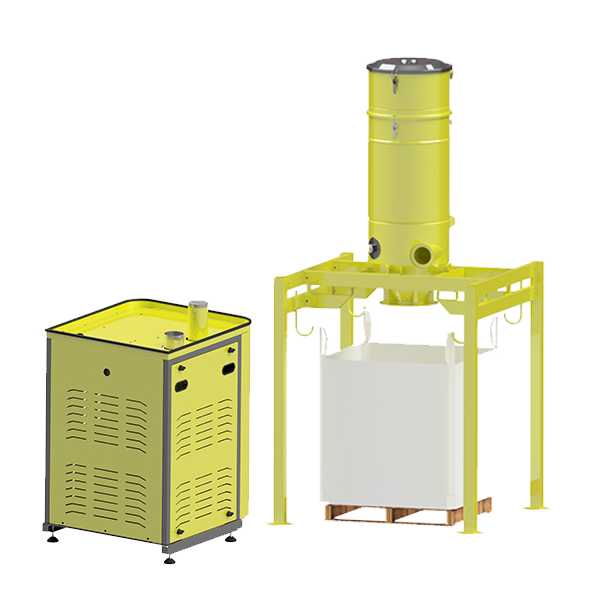

Industrial dust collectors for weighing zones

Another problem the chemical-pharmaceutical industry faces is the fine dust during product weighing, which can escape and remain suspended in the air, creating a hazard for workers and the work environment. Vacuuming directly at the source with an industrial dust collector is the most efficient form of protection.

Our dust collectors keep production lines clean and working, guaranteeing: