Oil and chips

Industrial vacuum cleaners for CNC

and tank maintenance

Cleaning work spaces and servicing tool machines are important activities for engineering industries to prevent machine downtime that undermines machinery productivity. The Meka industrial vacuum cleaner line makes it possible to suction chips and emulsions, separate them, and put the filtered, reusable oil back into the system, ensuring significant financial savings on purchasing new oil.

These industrial vacuum cleaners make it possible to:

Save on the cost of purchasing new oil

Save on the costs of used oil disposal

Service and clean tool machines quickly and easily

Limit stand-by time for machine maintenance

Tank and reservoir maintenance

Due to the presence of metal chips in oil reservoirs during operations, filtering and reusing the emulsions after an operating cycle is difficult.

It is possible to suction the oil and chip mixture from any type of tank, big or small, using an industrial vacuum cleaner, separating the oils from the chips and allowing the filtered emulsions to be reused in the following work cycle.

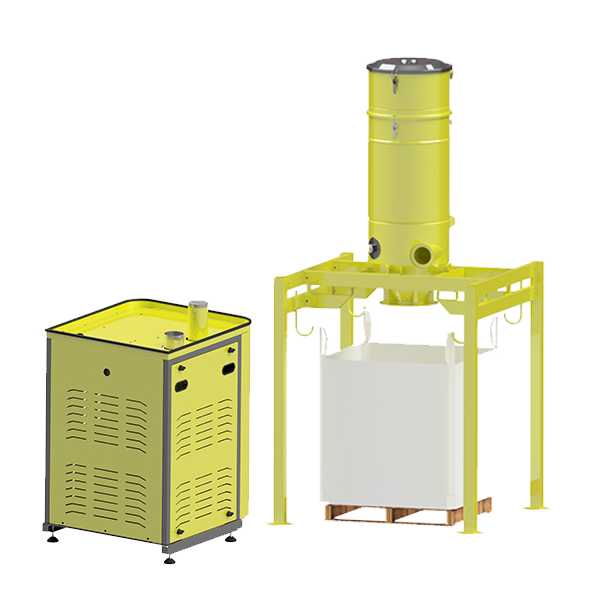

Recommended for this application

Oil filtration: how does it work?

The oil and chips are suctioned in the filter chamber of the vacuum cleaner, where they are filtered and retained by the sieve grid basket for easy collection.

The filter and floating device prevent the oil or oil fog from getting into the motor and damaging the vacuum cleaner. The oils are then collected in the tank and returned to the CNC machine via the discharge system, resulting in savings on the costs of purchasing new oil. The discharge systems can be either manual or automatic, allowing the oil-chip mixture to be suctioned and the filtered oil to be re-introduced simultaneously.

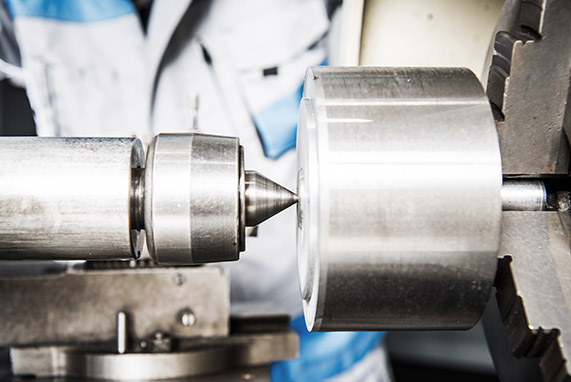

Industrial vacuum cleaners for chips

Finishing and cutting operations executed using numerical control machinery that does not use oil produces a significant amount of chips. Their removal and clean-up require time and frequent interruptions to production cycles, slowing the progress of work.

Using a vacuum cleaner designed to efficiently remove chips during processing ensures that all the contained chips are efficiently cleaned up, even in large amounts.

Industrial vacuum cleaners for additive manufacturing

Highly explosive dust such as titanium, aluminium, or carbon are used in development processes like additive manufacturing.

To eliminate any risk of explosion, it is important to make sure the dust is rendered completely inert during removal, ensuring:

No cross-contamination among various types of dust or outgoing batches.

Greater protection in controlling dust

Greater operator safety

Mastervac has developed a range of Atex-certified vacuum cleaners with inert collection tank that submerges the vacuumed explosive material in an oil, rendering them inert. The combustible dust is removed safely and submerged immediately after being vacuumed.