Material handling

Material handling

Handling material inside a manufacturing facility is a critical phase in terms of safety and preventing product contamination. Oftentimes, in fact, especially in food, pharmaceutical, and chemical companies, the most important prerogative is keeping the product clean and uncontaminated, preventing it from coming into contact with any external elements.

Another important aspect in terms of product handling regards its integrity because, especially in the event of larger particle products, there can be risks of breakage within the production or packaging chain.

In a great many manufacturing companies, the choice for moving the product from one point to another is a conveyor belt or bucket elevator. However, these systems can be disadvantageous if compared to a pneumatic conveyor system for the following reasons.

Consigliati per questa applicazione

Prevents cross-contamination

A pneumatic conveyor is a completely closed material handling system that prevents any external substances or elements from coming into contact with the product while it is being transferred. From the pick-up point to the drop-off point, the product travels inside thoroughly cleanable, sterile, and completely closed piping and hoppers, an exclusive advantage that is not possible to find in other handling systems.

Completely bespoke structure

A pneumatic conveyor is studied down to the last detail in order to be made to the specific size request of each customer, based on the configuration of their company, the manufacturing environments, and, naturally, according to the unique features of the material to handle. The great advantage compared to a bucket elevator or a belt are, therefore, the extremely modular features.

Absolute system flexibility

Choosing to handle material via a pneumatic conveyor system allows customers to make better use of spaces, with a system that implements flexible hoses to reach even long distances, installing the conveyors directly onto the production machines.

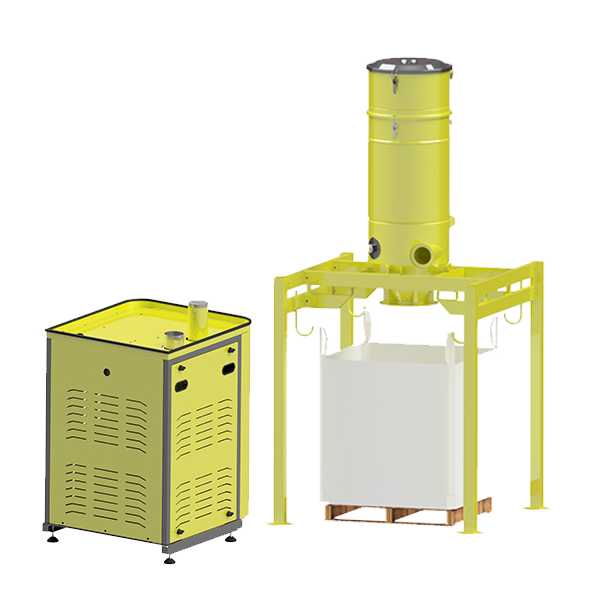

Instead, the suction units can be easily put into a utility room, thereby reducing the footprint in the operating work space.